General contents

Organization profile

Strategy

Corporate governance

Stakeholder engagement

Reporting practices

SASB

Significant contents

Economic performance

Legal compliance

Labor conditions and relations

Occupational health, safety and welfare

Ethics and anti-corruption

Consumption and energy efficiency

Water management

Materials

Consumer health, safety and welfare

Quality and safety in the value chain

Transparency in product information

Innovation

IP-8. Policies and procedures to communicate to consumers

Labeling Requirements

The pertinent regulatory labeling requirements for the product market vary by category. For the national market, we apply the specific Mexican Official Standard (NOM). If there is none, we apply the general laws and regulations, such as: Product and Service Health Control: From the General Health Law on matters of health control of activities, establishments, products and services; Resolution determining additives and coadjutants in food, beverages, and supplements, their health use and provisions; Resolution determining prohibited or permitted plants for teas, infusions, and edible vegetable oils; among others. For the case of export products, we apply the applicable regulations from the country to which we will be exporting.

As a volunteer practice that goes beyond the legal requirements, we review the sub-ingredients of the raw materials included in the formula to evidence any additive or contaminant that may affect the innocuity of the product. Additionally, we request results of contaminant analysis from some vendors, depending on the nature of the ingredient or product both for domestic and export consumption. In some cases, we send such information to be verified with specialized agencies or with bromatology studies in the destination country.

Information on content and ingredients

All our products that correspond to the food, non-alcoholic beverages, and food supplement categories include the list of ingredients and relevant nutritional information.

In food and beverages, we mandatorily include energy content, proteins, total fat, saturated fat, carbohydrates, total sugars, dietary fiber, and sodium.

In food supplements, we include energy content, proteins, total fat, carbohydrates, and sodium by portion per 100g of product.

The main source of nutritional information is the label. However, some of the websites of the company include such information. Additionally, the 01 800 customer service line, for each of the food and non-alcoholic beverage brands has the relevant updated information. All statements must be made in labels that must be supported with scientific evidence to be able to include these in the label and comply with the applicable regulations for the product and market in which the product will be sold.

Within our internal guidelines, we have agreed to indicate in the label:

- Artificial or natural coloring; natural, artificial, or identical flavoring to the natural one; hydrolyzed protein and MSG are declared as such

- There is no declaration of Genetically Modified Organisms (GMO) according to national law

- We declare sweeteners as required by the Additives Resolution

- We declare all present allergens and those that may be present in the product

- Practically none of our products is fortified, unless it is a requirement mandated by regulations

- Methods used in food processing to maintain their innocuity

In 2021, 2.4% of the total products sold corresponds to products with reduced sodium, saturated fat, trans fat, or added sugar.

SASB. Sustainability accounting standards

| Subject | # | Description | ||||||||||||||

| Energy management | FB-PF-130a.1 | (1) Total consumed energy: 1,187,741 Gj

(2) Percentage of electricity from the grid: 30.8% (3) Renewable percentage: 69.2% (4) Percentage of water consumed in regions with high or extremely high water stress: 100% |

||||||||||||||

| Water management | FB-PF-140a.1 | (1) Total extracted water 1,295.0 Mil m3

(2) Total consumed water: 514.7 Mil m3 (3) Percentage of each of the regions with high or extremely high hydric stress: 99.9% |

||||||||||||||

| FB-PF-140a.2 | Number of non-compliance incidents associated with permits, standards, and regulations of the amount and/or quality of water: 0 | |||||||||||||||

| FB-PF-140a.3 | Description of the risks of water management and discussion of strategies and practices to mitigate these risks.

Currently, diagnostics are carried out to identify initiatives for the use of rainwater. There is a description of the related impacts by source of extraction, consumption and water discharges in the GRI indicator 303-1. At Grupo Herdez we have the objective of reducing water consumption per ton produced by 25.0% by 2030 compared to 2018 (base year), which is equivalent to achieving a consumption of 1.98 m3 per ton produced by 2030. SDG 6: Clean water and sanitation SDG 12: Responsible consumption and production The performance indicator is expressed in water use intensity, expressed as the volume of water (m3) per ton produced.

The scope of water intensity includes the following plants: Herdez El Duque Industrial Complex (Barilla, El Duque and Cogeneration Plant), Coronel Espinosa Plant, Mexico Plant (Zumpango), Herdez San Luis Potosí (Industries), Santa Rosa Tomates, Santa Rosa Vegetales, Herdez Villagrán, Nutrisa Plant and Lagos de Moreno Plant. These plants represent 100% of the facilities where Grupo Herdez has operational control and, therefore, represent 100% of the volume of water withdrawn. The distribution centers included are: Mexico, San Luis Potosi, Los Mochis, Merida, Guadalajara, Monterrey, CAF Lagos de Moreno and Tijuana. These facilities represent 90% of the water withdrawn from all distribution centers within the scope specified for this Framework. Water consumption refers to the volume of water withdrawn from any source: subway (well), surface (river, canal, etc.), municipal network, pipes, wastewater and/or rainwater used in the plants and distribution centers for production and various uses such as boilers, cooling towers and services in general. |

|||||||||||||||

| Food Safety | FB-PF-250a.1 | Global Food Safety Initiative (GFSI) Audit

(1) Non-conformity rate: 5.1 (2) Rate of corrective action associated for non-conformity cases (velocity): 4.7 (a) Higher non-conformities: 6.0 (b) Lower non-conformities: 4.5 Subsections a and b correspond to the % of the rate of corrective actions corresponding for non-conformity cases (velocity). |

||||||||||||||

| FB-PF-250a.2 | Percentage of ingredients from facilities of Level 1 vendors certified by a food safety certification program recognized by the Global Food Safety Initiative (GFSI).

76% of vendors of the Group have the GFSI (Global Food Safety Initiative) certification, which seeks to develop competencies and capacities to create global food systems, which are uniform, protected against the contaminants during the food chain and efficient operations. This corresponds to 88% of vendor expenses. |

|||||||||||||||

| FB-PF-250a.3 | (1) Total number of notifications of food safety violations received: 0

(2) Corrected percentage: 0 |

|||||||||||||||

| FB-PF-250a.4 | (1) Number of notifications issued: 0

(2) Total amount of food products recalled: 0 |

|||||||||||||||

| Health and Nutrition | FB-PF-260a.1 | Income from products labeled and/or marketed to promote health and nutrition attributes: $33,372,828 MXN | ||||||||||||||

| FB-PF-260a.2 | Discussion of the process to identify and manage products and ingredients related to nutritional and health concerns among consumers.

HEALTH: We review the ingredients that compose the formula of the different products, and we do it exhaustively to ensure their compliance with applicable regulations, not only local but also, as applicable, of the country where we export. All labels of our products require compliance with labeling Mexican official standards (NOM) and these contain the requirements we must comply with; we make an initial review of compliance of the ingredients. NUTRITION: All products have nutritional information and an ingredient list that provides information to consumers, according to compliance with the regulations in force of the countries where the products are marketed. Additionally, we are increasingly aware that there are increasingly more consumers concerned with their health. We started a nutritional mapping of the entire food and beverage portfolio of the Group, identifying the presence of certain artificial additives and the number of warning seals of nourishments that these contain, to then identify possible reduction in added critical nourishments, or eliminate artificial additives. |

|||||||||||||||

| Product labeling and marketing | FB-PF-270a.1 | Percentage of advertising prints

(1) Made for children: 0 (2) Made for children that promote products that comply with dietary guidelines: 0 |

||||||||||||||

| FB-PF-270a.2 | Income from products labeled as:

(1) Containing Genetically Modified Organisms (GMO): 0 (2) Non-GMO: 0 Regarding GMOs in Mexico, we do not have any regulations regulating GMOs. |

|||||||||||||||

| FB-PF-270a.3 | Number of incidents of failure to comply with the regulatory or industry marketing and/or labeling codes: 0 | |||||||||||||||

| FB-PF-270a.4 | Total amount of monetary losses resulting from legal procedures associated with labeling and/or marketing practices: 0 | |||||||||||||||

| Management of the packaging life cycle | FB-PF-410a.1 | (1) Total package weight: 120,484 Ton

(2) Percentage made from recycled and/or renewable materials: 11.5% (3) Percentage that is recyclable, reusable, and/or compostable: 99.5% |

||||||||||||||

| FB-PF-410a.2 | Discussion of strategies to reduce the environmental impact of containers throughout their life cycle.

1.- Grupo Herdez developed the Life Cycle Analysis (LCA) for the main product categories (salsas, mayonnaise, tea, avocado, Nutrisa® frozen yogurt, ice cream, pasta, tomato puree, vegetable salad). We have selected the product that is most representative of the category and developed the particular LCA for the purpose of obtaining greater information. Some have a third party expert report called “critical review”. 2.- These LCA were carried out considering the stages of the life cycle (raw material, packaging material, including transportation of both, manufacturing, transportation/distribution, use and end of life). In the end of life stage we identified the environmental impacts of the packaging and containers to conduct the sensitivity analysis to simulate scenarios of potential impacts in case of substantial future changes in: type, volume, recyclability, recycling increase rate, among others. 3.- Preparing these LCA has allowed us to generate other initiatives and actions on matters of packaging circularity. |

|||||||||||||||

| Environmental and social impacts of procurement or ingredients | FB-PF-430a.1 | Percentage of food ingredients that are certified according to third party environmental and/or social standards

Percentages per standard: 53.7% In 2021, we acquired 468,469 tons of raw materials and agricultural raw materials. These correspond to 53.7% of the total, and comply with the Sustainable Agricultural Program implemented by the Group. |

||||||||||||||

| FB-PF-430a.2 | Vendor social and environmental responsibility audit

Through the Sustainable Agriculture Program, we evaluate 100% of the new vendors every 6 months, complying with the rules checklist. At the end of the 2021 cycle, we completed the evaluation with 30 vendors (December 2021). 29 of 30 vendors comply with the sustainable agriculture program, which represents 96.6% compliance at the closing of December 2021. (1) Non-compliance ratio: 3.4% (2) Ratio of associated corrective actions for cases of non-compliance: 0 We do not have a division between higher and lower non-compliance. |

|||||||||||||||

| Ingredient Procurement | FB-PF-440a.1 | Percentage of food ingredients from regions with high or extremely high hydric stress: 93.2%

Note: this calculation was carried out considering the total tons of ingredients. |

||||||||||||||

| FB-PF-440a.2 | List of priority food ingredients and discussion of procurement risks due to environmental and social considerations.

Ingredients: Oil, starch, and sweeteners, standard sugar, refined sugar, dry peppers, Guajillo peppers, peppers, green jalapeño, jalapeño pepper, fresh red poblano pepper, frozen strawberry, mole cookie, sweet yellow corn, clear honey from the altiplano, clear honey from the coast, cactus, tomato paste, salt, semolina, tomato, green tomato, and egg yolk. The strategic environmental and social risk management method is the Sustainable Agriculture Program, which consists of guiding, training, overseeing, and following-up on the production practices of our agricultural vendors, having environmental conservation and improvement as the basis, putting special attention to protected zones or areas, use of hydric resources, soil conservation, and air cleaning. We have a team of internal auditors that evaluate and follow-up on the status of the plots of land. This is carried out through a checklist to comply with the rules, which measures the progress and points of improvement of each vendor. At the end of the 2021 cycle, we completed the evaluation with 30 vendors. We apply this program through compliance Rules:

The main benefits of this program are:

Our goals regarding water are established based on indicators of water consumption and wastewater discharge carried out in each facility. Currently, each facility identifies areas of opportunity in its processes and makes estimations on the potential savings that it may provide to then propose an achievable annual goal. Such goals are related to the local context of their locations based on the basic and general concept of preventing unnecessary water extraction and reducing to the extent possible the contaminants discharged in compliance with the regulations applicable to us. With the actions carried out continuously to reduce water consumption and recycle treated wastewater, we seek to reduce the impacts on the resource. Additionally, in the future, we intend to define the water footprints of each plant and associate their reduction to assist in the local sphere. |

|||||||||||||||

| Activity | FB-PF-000.A | Weight of goods sold: 569,917 metric tons | ||||||||||||||

| FB-PF-000.B | New production facilities: 13 plants |

IP-7. Research and Development Management

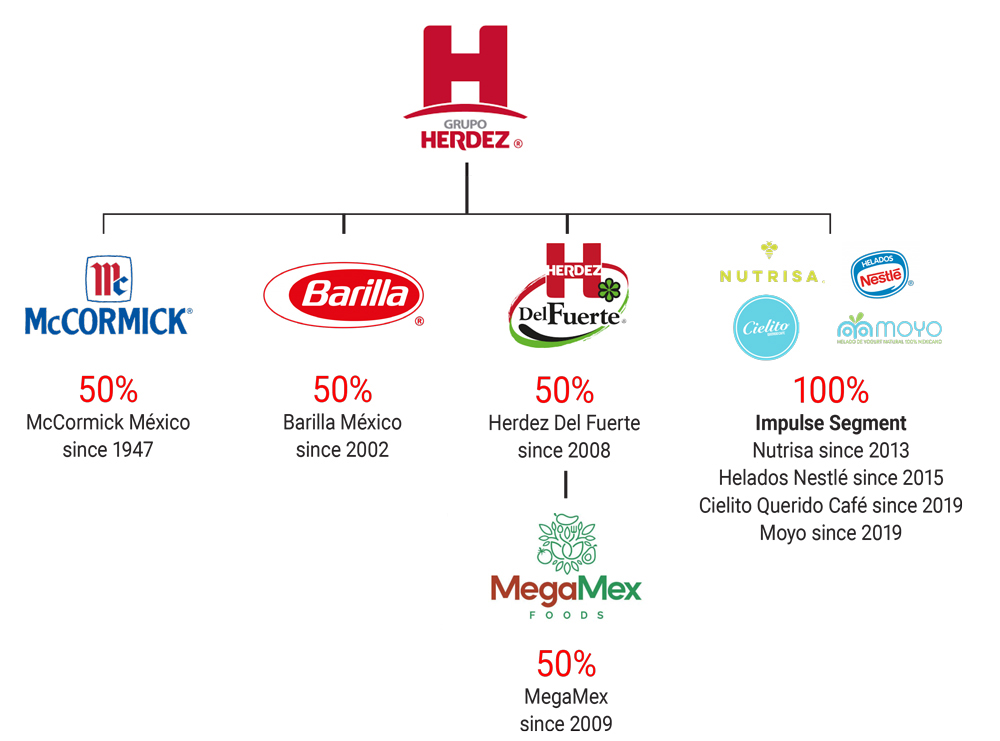

At Grupo Herdez we seek to foster open innovation, to contribute to external knowledge and complement our internal strategy.

Research and Development expenses during the past 3 years have been:

| Unit | 2021 | 2020 | 2019 | |

| Total R&D Expenses | Expressed in Mexican pesos (MXN) | $41,056,045 | $36,782,615 | $8,155,422 |

| Number of R&D employees | Amount | 83 | 73 | 57 |

| R&D Expenses as a % of Sales | MXN Expenses / % of Net Sales | 17.3% | .15% | 7.2% |

A product is considered new for 5 years after its launch.

| Type of Innovation | Income Percentage

(in %) |

| New products or services marketed in the past year | 6.4% |

| Products with significant improvements marketed in the past year | 3.2% |

| Products or services without changes, or minimally modified | 90.4% |

IP-1. Client and customer relations

We have several communication channels to address the comments and needs of our customers and consumers.

Points of Contact:

01-800 Lines: Each Brand has an assigned number in which product quality problems, complaints, or suggestions are resolved.

Digital Media: We have official websites for most of our brands, where consumers and customers may find all product information. We additionally have more than 20 brand profiles in social media, where the “Q&A” interaction allows us to monitor our good choices, concerns, and questions from our customers.

| Brand | Website | |||

|---|---|---|---|---|

| Aires de Campo® | https://airesdecampo.com/ | AiresDeCampo | airesdecampo | aires_de_campo |

| Barilla® México | https://www.barilla.com/es-mx | XBarillaMX | barillamex | BarillaMexico |

| Blasón® | https://cafeblason.mx/ | CafeBlason | cafeblason | NA |

| Búfalo® | https://bufalo.com.mx/ | SalsaBufalo | salsabufalo | salsaBufalo |

| Carlota® | https://www.mielcarlota.com.mx/ | MielCarlotaMexico | mielcarlota | NA |

| Del Fuerte® | https://delfuerte.com/ | DelFuerte | delfuertem | NA |

| Del Fuerte® | https://delfuerte.com/ | DelFuerte | delfuertem | NA |

| Cielito Querido Café® | https://cielitoquerido.com.mx/ | CielitoQueridoOficial | cielitoqueridooficial | CielitoQuerido |

| Moyo® | https://www.moyo.com.mx/ | MoyoYogurt | moyoyogurt | moyoyogurt |

| Doña María® | https://donamaria.com.mx/ | MoleDonaMaria | donamariamx | NA |

| Embasa® | https://embasa.com.mx/ | embasamx | NA | NA |

| Frank’s México® | https://franksredhot.com.mx/ | SalsaFranksMx | franksredhot_mx | NA |

| French’s México® | https://frenchs.com.mx/donde-comprar/zona-valle-de-mexico | FrenchsMexico | frenchsmx | NA |

| Herdez® | https://www.herdez.com.mx/ | HerdezConfianza | herdezmexico | NA |

| Helados Nestlé® | https://www.nestle.com.mx/ | heladosnestlemx | heladosnestlemexico | HeladosNestle |

| McCormick México® | https://www.mccormick.mx/ | McCormickMexico | mccormick_mx | NA |

| Nutrisa® | https://www.nutrisa.com/ | NutrisaMx | nutrisamx | NutrisaMX |

| Yemina® | https://www.yemina.com.mx/ | PastaYemina | pasta_yemina | NA |

| Kikkoman® México | https://www.kikkoman.com.mx/ | KikkomanMexico | kikkoman_mexico | NA |

| Corporate and Corporate Social Responsibility | Website | |||

| Grupo Herdez | https://grupoherdez.com.mx/ | GrupoHerdezMX | NA | GrupoHerdezMx |

| Fundación Herdez | https://fundacionherdez.com/ | FundacionHerdezAC | fundacion.herdezac | HerdezFundacion |

| Saber Nutrir® | https://www.sabernutrir.com.mx/ | sabernutrir | programasabernutrir | NA |

| Food Service | https://herdezfoodservice.com.mx/ | herdezfoodserviceoficial | herdezfoodservice | HerdezFS |

All our corporate brands and accounts have an account on YouTube, except for: Blasón®, Embasa®, Helados Nestlé® and Kikkoman® México.

417-3. Marketing incidents

Neither Grupo Herdez, S.A.B. de C.V., nor its subsidiaries have failed to comply with marketing communications in 2021.

417-2. Product labeling incidents

Neither Grupo Herdez, S.A.B. de C.V., nor its subsidiaries have failed to comply with the product information and labeling of products and services in 2021.

417-1. Product labeling requirements

All labels of our products comply with labeling Mexican Official Standards (NOM), and these have the requirements that we must comply with.

We conduct an initial review of compliance of the ingredients. We perform the review of the ingredients that compose the formula of the different products exhaustively to ensure compliance with the applicable regulations, not only locally, but also, as applicable, of the countries to which we export.

- Product Health Control Regulations.

- NOM-050-SCFI-2004: Commercial Information; General Product Labeling.

- NOM-051-SCFI/SSA1-2010: General Labeling Specifications for Food and Non-Alcoholic Beverages Prepackaged Food – Commercial and Health Information.

IP-6. Agricultural Sustainability

Sustainable Agriculture Program

The program consists of guiding, training, overseeing, and following-up on the production practices carried out by our agricultural vendors, having as their basis the conservation and improvement of the environment, giving special attention to protected zones or areas, use of hydric resources, soil conservation, and air cleaning.

We apply this Program through compliance Rules:

- Preservation of biodiversity

- Air, water, and soil protection

- Energy and climate change

- Waste management

- Integrated crop management

- Agrochemical reduction

- Health and safety

- Decent work

- Social responsibility

- Communication and participation

The main benefits of this program are:

- Promoting, incentivizing, and developing sustainable agriculture in our vendors as a new agricultural production culture.

- Reducing the use of pesticides to lower the environmental impact and promote adequate use of agrochemicals (BUMA).

- Preserving soil, air, and water quality in farm areas and their surrounding areas.

- Incentivizing practices to improve soil quality.

- Promoting practices for efficient management and use of resources, favoring reduction, reuse, and recycling.

- Promoting the protection of sensitive or protected areas and species.

Audit

To give continuity and validity to the program, we have a team of internal auditors that assesses and follows-up on the condition of the plots of land. This is carried out through a checklist, which measures the progress and points of improvement of each vendor.

Mid 2021, we had 32 evaluated vendors (January to June 2021) at the end of 2021, we had evaluated 30 vendors (December 2021).

29 of the 30 vendors comply with the program, which represents 96.6% compliance as of the closing of December 2021.

The main existing controls to monitor the progress of the implementation of the programs are:

- Providing document control at the start of the agreement. Frequency: annual.

- Periodic oversight of each vendor: Frequency: every fifteen days.

- BPA audits. Frequency: Quarterly.

- Water, soil, and fruit analysis. Frequency: water and soil one once. Fruit, on a monthly basis.

- Tours. Frequency: monthly.

- Activity reports of the Agricultural Auditors: Frequency: weekly.

Use of agrochemicals

The main method to reduce the use of agrochemicals is under the Integrated Crop Management (use of biological products), mainly:

| Fungicides | Use of organic fertilizers and beneficial microorganisms |

| Insecticides | Use of beneficial fungi, bacteria, and insects |

| Fertilizers | Use of organic fertilizers (compost, leachates, shoot) |

From our total agricultural vendors, the compliance percentage of the Good Use of Agrochemical Management is 90%, the same percentage as last year.

*Note: The program only covers fresh raw material vendors, as a first stage, these are onion, tomato, pepper, cilantro vendors, among others.

409-1. Operations with a child labor risk

In our Vendor Code of Conduct, we have the minimum guidelines that our current and potential vendors must comply with respect to social and environmental conditions for development of their operations and services.

This document is based on the standards of the International Labor Organization (ILO), the ten principles of the UN Global Compact, the Human Rights Policy, and the Code of Ethics of Grupo Herdez.

408-1. Child labor risk

We have strict control in our hiring processes, and a Vendor Code of Conduct, which each vendor must sign when establishing a business relationship with Grupo Herdez.

The code provides clauses that prohibit child labor or forced labor. The foregoing, as a measure to prevent the risk of using child labor throughout our value chain, especially in the most vulnerable sectors such as agriculture and fishery.

The Vendor Code of Conduct may be checked at: https://grupoherdez.com.mx//wp-content/uploads/2021/09/Codigo-de-Conducta-de-Proveedores-GH-25.junio_.2021-VF.pdf

204-1. Significant operations expenses

| Vendor | Domestic | Foreign |

| Raw materials | 91.2% | 8.9% |

| $5,911,780,523 | $574,191,675 | |

| Packaging materials | 96.8% | 3.2% |

| $121,375463 | $4,025,366 | |

| Agricultural raw materials | 100% | – |

| $1,097,000,000 | – |

Note:

All of our agricultural producers have operations in Mexico, distributed nationwide in the states of Aguascalientes, Baja California, Baja California Sur, Campeche, Chihuahua, Mexico City, Durango, Guanajuato, Hidalgo, Morelos, Nayarit, Nuevo León, Puebla, Quintana Roo, San Luis Potosí, Sinaloa, Sonora, Veracruz, Yucatán, and Zacatecas.

IP-9. Health and Nutrition Care Strategy Development

Within the Technical Department, the Scientific and Regulatory Affairs Department validates that the products developed at Grupo Herdez contain permitted ingredients, and in the dose indicated by the applicable regulation for each product category. Additionally, it determines the nutritional icons that the Front Labeling must have, for consumers to have the nutritional information that the product contributes.

We continue strengthening the internal nutritional criteria within the nutritional guidelines for development of new products of the entire Group, creating the categories and their respective nutritional criteria indicating the maximum content limits for added critical nourishments and specific indications that must be considered and/or must be complied with. In 2021, we incorporated 10 categories plus nutritional criteria tables.

This year, 3.2% of the total sales volume was of products with low contents of saturated fat, trans fat, sodium, or added sugar.

We improved the nutritional quality in 15 formulas of our products with some type of reduction of added critical nourishments (sugars, sodium, saturated fats). The formulas that had such nutritional improvement were:

a) Sodium reduction: All varieties of ground tomato from Del Fuerte®, and also the ground tomato formula for the Herdez® brand.

b) Sugar reduction: The formulas involved for this nourishment were 6 varieties of hard ice cream for the Nutrisa® brand and a formula (popsicle) for the Nestlé® brand.

c) Sweetener elimination: In the formula (popsicle) for the Nesté® brand.

This year, we carried out a nutritional mapping the purpose of which was to understand the amount of warning seals of existing critical nourishments in each formula, artificial conservative content, and also sweeteners and flavoring. We also identified the possibility of reducing added critical nourishments or otherwise reducing the number of warning seals.

416-2. Violation incidents

Neither Grupo Herdez, S.A.B. de C.V., nor its subsidiaries have failed to comply with the voluntary regulations or codes on health and safety matters on products and services in 2021.

416-1. Product impact evaluation

100% of the product portfolio, both domestic and export, are evaluated on health and safety matters to promote improvements.

On health matters:

-25.6% of the domestic product portfolio are of a better nutritional quality. Such percentage is represented by products that do not contain added critical nourishments (sugars, sodium, saturated fat), and products that had some reformulation in added critical nourishments.

– 2.7% of the domestic product portfolio was reformulated to improve the nutritional profile, eliminating or reducing the content of added critical nourishments (sugars, sodium, saturated fat), and eliminating sweeteners.

From the product design, raw material and packaging material selection, we conduct a risk assessment according to the market in which the product will be marketed, and based on this we establish the specifications and limitations to comply with. Additionally, we have external audits to obtain the certification in FSSC22K.

All new and existing products conform their specifications to National and official quality standards, and Export standards to CFR, FDA, and USDA, as applicable.

308-1. Our vendors have passed evaluation and selection filters in accordance with environmental criteria

Through the Sustainable Agricultural Program, we conduct the evaluation of 100% of new vendors every 6 months, complying with the rules checklist.

Mid 2021, we had 32 evaluated vendors (January to June 2021) at the end of 2021 we completed the evaluation with 30 vendors (December 2021).

29 of the 30 vendors comply with the program. This represents 96.6% compliance at the closing of December 2021.

301-3. Reused products and packaging materials

In 2021, we recovered and recycled 4.5 tons of cans through the “Recicla la Lata” initiative. For more information: https://porunmundomasvivo.com/

Grupo Herdez forms part of ECOCE, a non-profit environmental organization, which has a comprehensive post-consumption waste management plan. Through this alliance, we work to recover waste and integrate it to the recycling cycle, in addition to adopting and promoting environmental care and sustainability.

301-2. Used recycled inputs

At Grupo Herdez we are starting our path to circularity, and working on specific initiatives to achieve our goals for 2025. On the subject of recycled inputs, the materials that contain these are derivatives of corrugated carbon such as small boxes, boxes, and trays.

| Recycled materials 2019 | 2.6% |

| Recycled materials 2020 | 2.2% |

| Recycled materials 2021 | 11.5% |

301-1. Materials used by weight and volume

In 2021, we consumed materials within 3 categories: agricultural raw materials, non-perishable raw materials, and packaging materials.

Renewable materials

- Agricultural raw materials: 163, 740 Ton

- Raw materials: 304,729 Ton

- Packaging materials: 118,695 Ton

Non-renewable materials

- Packaging materials: 1,789 Ton

306-5. Bodies of water affected by water poured and/or run-off

Discharges of wastewater from the facilities of Grupo Herdez are mainly discharged in the municipal sewage network. For the case of discharges to surface bodies of water or federal channels, we do not have technical evidence of their impact. Even so, all discharged water is previously treated, and the volumes are low/medium.

306-4. Transportation of hazardous waste

At Grupo Herdez, we do not transport, import, export, or treat any hazardous waste. The hazardous waste generated in the Group is sent to collection centers and/or controlled confinement centers.

306-3. Significant spills

We did not have any spills of material, waste, substances, and/or liquids in 2021.

306-2. Types of waste and elimination methods

This year, we generated 45,515 tons of hazardous and non-hazardous waste, a 31.6% year over year, due to an increase in production, the addition of the waste volume at the Coronel Espinoza plant; greater control of the health and safety conditions resulting from the pandemic, in addition to the generation and handling of greater volumes of obsolete equipment. To compensate for this increase, we were able to increase recycling of the waste generated by 86.6%.

Total weight of hazardous waste by elimination method

| Elimination method

Tons |

2021 | 2020 | 2019 |

| Recycling | 14 | 15 | 71 |

| Pouring | 50 | 51 | – |

| Others (final disposal) | 0 | – | 43 |

| Total | 64 | 66 | 114 |

Total weight of non-hazardous waste by elimination method

| Elimination method

Tons |

2021 | 2020 | 2019 |

| Recycling | 39,383 | 28,577 | 31,604 |

| Others (sanitary landfill, including special handling waste and non-valorized urban solid waste) | 6,067 | 5,950 | 10,327 |

| Total | 45,450 | 34,527 | 41,931 |

Total weight of the waste generated during the past 4 years

| Waste generated

Tons |

2021 | 2020 | 2019 | 2018 |

| 45,515 | 34,594 | 42,045 | 34,231 |

Note: We made an adjustment to the 2020 figures, eliminating the Avomex plant, which does not belong to the own operations of Grupo Herdez.

306-1. Water discharges by quality and use

| 2021 Pour currents |

Volume (m3) |

| Discharge to federal sewage | 542,566 |

| Discharge to municipal network | 165,246 |

| Discharge to the subsoil | 69,156 |

| Other discharges | 0 |

| Total | 776,968.6 |

Notes:

- The total volume of water discharges in 2021 was 776,968.6 m3, which represents a 7% increase with respect to 2020 due to the addition of discharge volumes at the Coronel Espinoza plant, and the increase in the number of equipment and facilities washings that we implemented for health and safety reasons due to the pandemic. Compared with the discharges per ton produced, there is no increase, since for both years we have an indicator of .75 m3 per ton produced.

- Treated wastewater is discharged to federal and municipal recipient bodies, and it complies with the maximum permissible limits established by the relevant Mexican official standards (NOM-001-SEMARNAT-1996 and NOM-002-SEMARNAT-1996).

- The treatment plants of Grupo Herdez are designed specifically for each facility and for the type of effluent to be treated, and thus, to be able to provide adequate treatment for processed water and, as applicable, sewage water.

Quality of discharged water

For 2021, the estimated amounts of liquids poured via wastewater that is treated at Grupo Herdez expressed in tons are:

- GREASES AND OILS: 6.40 Ton

- OBD: 39.72 Ton

- OCD: 169.15 Ton

- TSS: 36.08 Ton

- TDS: 273.52 Ton

- SS: 0.09 Ton

303-5. Water Consumption

The volume of rainwater collected and stored on an annual basis is 76 megaliters, corresponding to the maximum installed capacity.

Total consumption of water, in megaliters, for each facility in areas with hydric stress

| Source | 2021 | 2020 | 2019 | |||

| Total volume | Volume in areas with water stress | Total volume | Volume in areas with water stress | Total volume | Volume in areas with water stress | |

| Rivers and lakes | 231.8 | 231.8 | 217.3 | 217.3 | 229 | 229 |

| Wells | 273.4 | 273.4 | 310.3 | 310.3 | 396 | 355 |

| Municipal network | 3.5 | 3.5 | 4.4 | 4.4 | 0 | 0 |

| Others | 5.8 | 5.8 | 6.1 | 6.1 | 11 | 11 |

| Total | 515 | 515 | 538 | 538 | 637 | 596 |

Total consumption of water, in megaliters, for each facility in areas with hydric stress

| Source | Barilla Plant | El Duque

Plant |

Mexico Plant | Industrias Plant | Santa Rosa Tomato

Plant |

Santa Rosa Vegetable Plant | Villagrán

Plant |

Nutrisa

Plant |

Lagos

Plant |

Cogeneration Plant | Tea Plant | CAF Lagos |

| Rivers and lakes | 0 | 0 | 0 | 0 | 161.3 | 56.0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Wells | 44.8 | 6.8 | 32.6 | 115 | 0 | 0 | 2.3 | 0 | 94.6 | 13.6 | 0.07 | 0 |

| Municipal network | 0 | 0 | 0 | .8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3.6 |

| Water from tank trucks | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6.16 | 0 | 0 | 0 | 0 |

| Total | 515 | |||||||||||

Notes:

- The reported consumptions are measured directly through measurement instruments that are overseen and some of them certified by the federal, state, and municipal authorities. These consumptions are reported to such authorities through different reporting forms and mechanisms.

- The volume of rainwater is an estimated volume of what Complejo Duque de Herdez, Mexico Plant, and Mexico Distribution Center recover and use for garden watering.

- Since we are not using rainwater in the production processes, we will be reporting separately.

303-4. Water discharges

Water discharges by source

| Discharge Source | Volume in ml | ||

| 2021 | 2020 | 2019 | |

| Rivers, lakes (federal bodies) | 543 | 509 | 477 |

| Municipal network (municipal sewage) | 165 | 154 | 286 |

| Others (subsoil) | 69 | 63 | 60 |

| Total | 777 | 726 | 823 |

For the following sources: Underground (wells); seas, oceans; rainwater and discharged water from another organization, we did not carry out discharges.

Volume by discharges in areas with hydric stress

| 2021 | 2020 | 2019 | ||||

| Total Volume (Ml) | Areas with hydric stress | Total Volume (Ml) | Areas with hydric stress | Total Volume (Ml) | Areas with hydric stress | |

| Other water (> 1,000 mg / l of total solids dissolved) | 777 | 776 | 726 | 726 | 823 | 702 |

For freshwater, there are no discharges.

Note: We made an adjustment to the 2020 figures, eliminating the Avomex plant, which does not belong to the own operations of Grupo Herdez.

We took as a hydric stress determination criteria which is reported by Aqueduct Water Risk Atlas 2019 since it is an internationally recognized tool with the exception of Merida, where we considered the CONAGUA criteria by considering it more adjusted to the reality of the country.

Wastewater Treatment

| Treatment Level | Method to determine the type of treatment |

| Mainly secondary (biological) treatment followed by simple tertiary treatment | The treatment system of each facility is planned and designed in accordance with the characteristics of the wastewater generated and the discharge conditions that must be complied with, however, all of our treatment systems generally have the following treatment process:

|

Priority concern substances for water discharge

Substances: Oxygen Biochemical Demand (OBD), Total Suspended Solids (TSS), Total Dissolved Solids (TDS), Sedimentable Solids (SS), Hydrogen Potential (HP), Electrical Conductivity, Temperature, Greases and Oils.

Method to define its importance: Compliance with national standards and particular discharge conditions established by the Mexican government.

Substance: Oxygen Chemical Demand (OCD).

Method to define its importance: Standard determined for operational control of the system.

The standards that the facilities of Grupo Herdez comply to respect the priority substance discharge limits are:

- NOM-001-SEMARNAT-1996: Establishes the maximum permissible limits of contaminants in wastewater discharges and national property

- NOM-002-SEMARNAT-1996: It establishes the maximum permissible limits of contaminants in wastewater discharges to urban or municipal sewage systems

- State Technical Standard NTE-SLP-AR-001/05: It establishes particular conditions for wastewater discharges to the drainage and sewage network of the Municipalities of San Luis Potosí, Soledad de Graciano Sánchez, and Cerro de San Pedro

- Particular Discharge Conditions: Established by federal authorities in accordance with Article 140 of the Regulations to the National Waters Law, which sets forth that to determine the particular discharge conditions, “The Commission” will consider the parameters and maximum permissible limits contained in Mexican Official Standards issued by the authorities with jurisdiction on matters of wastewater discharges and for treatment of water for human use or consumption, and the parameters and maximum limits derived from the Classification Declarations of National Waters Body published under the terms of Article 87 of the “Law”.

303-3. Water Extraction

Total water extraction, in megaliters, by source.

| Source | 2021 | 2020 | 2019 | |||

| Total Volume (Ml) | Areas with hydric stress | Total Volume (Ml) | Areas with hydric stress | Total Volume (Ml) | Areas with hydric stress | |

| Rivers and lakes | 737.8 | 737.8 | 702 | 702 | 669 | 669 |

| Underground (wells) | 531.9 | 531.4 | 537 | 537 | 770 | 604 |

| Municipal network | 11.3 | 11.3 | 15 | 15 | 23 | 4 |

| Rainwater | 0 | 0 | 0 | 0 | 0 | 0 |

| Wastewater from another organization | 0 | 0 | 0 | 0 | 1 | 1 |

| Others (Pipes) | 13.9 | 13.9 | 12 | 12 | 22 | 22 |

| Total | 1,295 | 1,294.5 | 1,266 | 1,266 | 1,484 | 1,299 |

Total water extraction, in megaliters, for each facility in areas with hydric stress

| Source | Installation (Plant or distribution center) | Volume 2021 | Volume 2020 | Volume 2019 |

| Rivers, lakes | Santa Rosa Tomatoes | 460 | 402 | 366 |

| Santa Rosa Vegetables | 477 | 298 | 300 | |

| Mochis Distribution Center | 1 | 1 | 2 | |

| Underground (wells) | Barilla | 40 | 51 | 47 |

| El Duque | 38 | 41 | 41 | |

| Mexico Plant | 81 | 77 | 77 | |

| San Luis Potosi Plant | 193 | 201 | 259 | |

| Villagran Plant | 36 | 28 | 39 | |

| Lagos de Moreno Plant | 110 | 111 | 129 | |

| Cogeneration Plant | 16 | 15 | 0 | |

| Tea Plant | 2 | 0.2 | 0 | |

| San Luis Potosi Distribution Center | 7 | 9 | 0 | |

| Mexico Distribution Center | 9 | 4 | 0 | |

| Merida Distribution Center | 0 | 0 | 0 | |

| Municipal network | San Luis Potosi Distribution Center | 2 | 4 | 7 |

| Mexico Distribution Center | 0 | 0 | 4 | |

| San Luis Potosi Plant | 0.2 | 1 | 0 | |

| Tea Plant | 0.5 | 1 | 0 | |

| Guadalajara Distribution Center | 0.6 | 1 | 0 | |

| Tijuana Distribution Center | 0.3 | 1 | 0 | |

| Monterrey Distribution Center | 0.5 | 0.5 | 0 | |

| CAF Lagos | 7 | 7 | 0 | |

| Others (Pipes and waste water) | Nutrisa | 13 | 13 | 0 |

| Total | 1,294.5 | 1,266 | 1,299 | |

In 2021, by type of facilities, the following facilities were taken from other sources due to their change of source to municipal network, when before it was with pipes:

- Tijuana Distribution Center

- Monterrey Distribution Center

- San Luis Potosí Distribution Center

Note: We made an adjustment to the 2020 figures, eliminating the Avomex plant, which does not belong to the own operations of Grupo Herdez.

303-2. Management of the impacts related to water discharges

The minimum standards established for the quality of the effluent discharges of Grupo Herdez are:

* Oxygen Biochemical Demand (OBD)

* Total Suspended Solids (TSS)

* Total Dissolved Solids (TDS)

* Sedimentable Solids (SS)

* Hydrogen Potential (HP)

* Electrical Conductivity (CE)

* Greases and Oils (G&O)

* Oxygen Chemical Demand (OCD)

Specific standards:

- NOM-001-SEMARNAT-1996:It establishes the maximum permissible limits of wastewater discharges and national property

- NOM-002-SEMARNAT-1996:It establishes the maximum permissible limits of contaminants in wastewater discharges to urban or municipal sewage systems.

- State Technical Standard: NTE-SLP-AR-001/05, which established particular conditions for wastewater discharges to the drainage and sewage network of the Municipalities of San Luis Potosí, Soledad de Graciano Sánchez, and Cerro de San Pedro.

- Particular Discharge Conditions: Established by federal authorities in accordance with Article 140 of the Regulations to the National Waters Law.

303-1. Interaction with water as a shared resource

Extraction

| Source | Extraction Method | Location and name of the body of water | Description of the related impacts |

| Rivers and lakes | Pumping | 1 at Canal Lateral 18+420 del Canal Valle del Fuerte, Cuenca Río Fuerte, Afluente canal principal Valle del Fuerte Distrito de Riego 075, Región Hidrológica Sinaloa, Localidad El Fuerte, Sinaloa. 1 at Canal Lateral 18+420 del Canal Valle del Fuerte, Cuenca Río Fuerte, Región Hidrológica Sinaloa, Localidad Campo 35, Ahome, Sinaloa. |

Potential depletion of the resource, although there is a low probability of this, due to the low extraction volumes |

| Seas and oceans | Not applicable | Not applicable | Not applicable |

| Underground (wells) | Submergible pump | 2 at Cuenca Presa San José Los Pilares y Otras, Acuífero San Luis Potosí, Región Hidrológica Salado en SLP San Luis Potosí. 1 at Cuenca Laja, Acuífero Valle de Celaya, Región Hidrológica Lerma-Santiago, Villagrán Guanajuato. 1 at Cuenca Río Verde Grande, Acuífero Lagos de Moreno, Región Hidrológica Lerma-Santiago, Lagos de Moreno, Jalisco. 1 at Cuenca Río Moctezuma, Acuífero Cuautitlán-Pachuca, Región Hidrológica Pánuco, Localidad Barrio de San Juan, Teoloyucan, State of Mexico. |

Potential depletion of the resource, although there is a low probability of this, due to the low extraction volumes for the case of San Luis Potosí, Guanajuato, Jalisco, and the State of Mexico |

| Municipal network | Direct supply by network | 1 at San Luis Potosí, SLP 1 at Tijuana, Baja California 1 at Monterrey, Nuevo León 1 at Tlaquepaque, Jalisco 1 at Lagos de Moreno Jalisco |

Potential depletion of the resource, although there is a low probability of this, due to the low extraction volumes |

| Rainwater (collected and stored directly by the organization) | Channel and ditch infrastructure for rainwater collection | 1 at Complejo Industrial Duque de Herdez in SLP, San Luis Potosí 1 at Complejo Industrial Herdez México in Cuautitlán, State of Mexico |

Not applicable |

| Wastewater of another organization | Not applicable | Not applicable | Not applicable |

| Tank truck water | Direct supply by tank truck | 1 at the municipality of Chalco, State of Mexico 1 at the municipality of Sabinas, Coahuila |

Potential depletion of the resource and potential water deficit in the region. Likewise, the extraction volumes are relatively low |

| Wastewater of the organization | Not applicable | 2 at Complejo Industrial Herdez México, at Cuautitlán, State of Mexico (1 at the plant and 1 at the distribution center)

|

México Plant and México Distribution Center recycled 69.3% and 100% respectively of their wastewater treated in garden watering |

| Source | Use of Extracted Water | Location where it was consumed | Description of related impacts |

| Rivers and lakes | Industrial (production, ancillary services, and sanitary services) | 2 at Los Mochis, Sinaloa | Potential depletion of the resource, although there is a low probability of this, due to the low extraction volumes |

| Seas and oceans | Not applicable | Not applicable | Not applicable |

| Underground (wells) | Industrial (production, ancillary services, and sanitary services) | 1 at Cuautitlán, State of Mexico

3 at San Luis Potos 2 at Lagos de Moreno Jalisco 1 at Villagrán Guanajuato |

Potential depletion of the resource, although there is a low probability of this, due to the low extraction volumes |

| Municipal network | Industrial (production, ancillary services, and sanitary services) | 1 at San Luis Potosí, SLP 1 at Tijuana, Baja California 1 at Monterrey, Nuevo León 1 at Tlaquepaque, Jalisco 1 at Lagos de Moreno Jalisco |

Potential depletion of the resource, although there is a low probability of this, due to the low extraction volumes |

| Rainwater (collected and stored directly by the organization) | Industrial (green area watering) | 2 at Cuautitlán, State of Mexico

1 at San Luis Potosí, SLP |

Reduction in the extraction and consumption of well water due to the use of rainwater to water green areas |

| Wastewater from another organization | Not applicable | Not applicable | Not applicable |

| Water from tank trucks | Industrial (production, ancillary services, and sanitary services) | 1 at Chalco, State of Mexico | Potential depletion of the resource and potential water deficit in the region. Likewise, the extraction volumes are relatively low |

| Wastewater of the organization | Industrial (sanitary services and green area watering) | 2 at Complejo Industrial Herdez México, in Cuautitlán

|

Mexico Plant recycles 35% and Mexico Distribution Center recycles 100% of the wastewater that they generate and treat, using it to water gardens |

Discharges

| Source | Discharge Method | Use of the discharge | Description of related impacts |

| Rivers and lakes | Direct discharge to the body of water through a drainpipe | Canal lateral del canal Valle del Fuerte, Cuenca Río Fuerte, Afluente main channel Valle del Fuerte Distrito de Riego 075, Región Hidrológica Sinaloa, Localidad El Fuerte, Sinaloa | Wastewater discharges are treated in accordance with applicable regulations, therefore, their significance level has not been determined |

| Seas and oceans | Not applicable | Not applicable | Not applicable |

| Underground (wells) | Direct discharge to the body of water through drainpipe | Wastewater discharges from the Lagos de Moreno Plant, San Luis Potosí Distribution Center, Tea y McCormick (Duque de Herdez) Plant are sent to the municipal sewage.

Wastewater discharges from the Herdez Villagrán Plant, and part from the Mexico Plant, are discharged in a federal sewerage. 100% of the wastewater of the Mexico Distribution Center and 69.3% of the wastewater from the Mexico Plant infiltrate the ground. |

Wastewater discharges are treated in accordance with applicable regulations, therefore, their significance level has not been determined |

| Municipal network | Gravity and direct conduction to the sewage or recipient body | Municipal sewage | Discharge of contaminants into a recipient body |

| Rainwater (collected and stored directly by the organization) | Pumping | Rainwater is used for green areas, and the remainder is sent to the drainpipe | Rainwater consumption prevents drinking water extraction from a well, therefore, the impact is positive, even though its significance has not been estimated |

| Wastewater from another organization | Not applicable | Not applicable | Not applicable |

| Water from tank trucks | Direct discharge to the body of water through a drainpipe | Wastewater discharges from the Nutrisa Plant are sent to the municipal sewage | Wastewater discharges are treated in accordance with applicable regulations, therefore, their significance level has not been determined |

| Wastewater from the organization | Gravity and direct conduction to the sewage | Municipal sewage |

The Mexico Plant recycled 69.3% and the Mexico Distribution Center recycled 100% of the wastewater that they generate and treat, using it to water gardens |

Note: The quality of wastewater discharges sent to recipient bodies of water is overseen through compliance with the maximum permissible limits established by the relevant Mexican Official Standards.

Basins where water is extracted by the organization:

| Basin | Description of related impacts |

| Cuenca Río Fuerte, Región Hidrológica Sinaloa, Localidades Campo 35, Ahome and El Fuerte, Sinaloa. | Extraction and Consumption:

Except for the Merida Distribution Center, our plants and distribution centers are located in basins and hydrological regions with low or very low water availability, but the consumption of our facilities are very low. Discharges: |

| Cuenca Presa San José Los Pilares and Others, Acuífero San Luis Potosí, Región Hidrológica Salado in San Luis Potosí. | |

| Cuenca Laja, Acuífero Valle de Celaya, Región Hidrológica Lerma-Santiago, Villagrán Guanajuato. | |

| Cuenca Río Verde Grande, Acuífero Lagos de Moreno, Región Hidrológica Lerma-Santiago, Lagos de Moreno, Jalisco. | |

| Cuenca Río Moctezuma, Acuífero Cuautitlán-Pachuca, Región Hidrológica Panuco, Localidad Barrio de San Juan, Teoloyucan, State of Mexico. |

Related impacts

Our goals regarding water are established based on water consumption and wastewater discharge indicators that are carried out for each facility. Currently, each facility identifies areas of opportunity in its processes and makes estimates on the potential savings that each may provide, to then propose a reachable annual goal. Such goals are unrelated to the local context of their locations.

Note: No analytical, holistic, or deep approach is applied to identify the potential impacts, rather we only intuitively consider the potential impacts that may be caused by the consumption volumes of water extracted at the sources and, due to the number of contaminants present in the wastewater discharged to the different recipient bodies of water.

IP-10. Percentage of renewable energy consumed in the organization

In 2021, 69.2% of the energy consumed by Grupo Herdez came from clean sources.

Renewable energy (wind) 41.5 %

Clean energy (cogeneration): 27.7%

305-7. Nitrous oxide (NOX), Sulfur oxides (SOX), and other significant air emissions

| Atmospheric emissions | 2021 (Ton) |

| NOx | 72.32 |

| SOx | 85.84 |

| POC (persistent organic contaminants) | NA |

| VOC (volatile organic compounds) | 1.16 |

| HAP (hazardous air pollutants) | NA |

| PM (particles) | NA |

| OTHERS | |

| CO | 24.57 |

| PS | 3.12 |

| COT | 3.72 |

| SO2 | 84.97 |

| SO3 | 0.86 |

| Filterable PS | 6.75 |

| NMCOV´s | 0.05 |

The methodology used is that of direct determination using specific emission factors for each type of contaminant, as recommended by the GreenHouseGas Protocol (GHGP) for emissions that come from direct fixed (stationary) and mobile sources.

To determine the emission factors to be used, we considered the provisions issued by the UK Department for Environment, Food and Rural Affairs (DEFRA), la US Environmental Protection Agency (EPA), and the Intergovernmental Panel on Climate Change’s (IPCC) 2006 Guidelines for National Greenhouse Gas Inventories, through the Mobile Combustión GHG Emissions Calculation Tools and Stationary Combustion GHG Emissions Calculation Tools that may be checked at the GHG Protocol Website.

On the other hand, although the data represents the Group’s concentrate, the estimate is based on specific data provided by each facility, considering fuel consumption -measured directly- in fixed and mobile sources of Grupo Herdez. Likewise, unit conversion factors based on the decimal metric system were used for the conversion from kilograms to tons.

305-6. Emissions that are damaging to the ozone layer

At Grupo Herdez we do not produce, import, or export type CFC-11 (R-11), and R-14 and R-22 substances.

The most used refrigerants are R-410A, R-134A, R-407C, R-404A, R-507, R-147, R-427, and R-MO99. For 2021, some facilities have already been established overseeing the non-use of R-22 refrigerant, and other prohibited refrigerants.

305-5. Reduction of greenhouse gas emissions

| Reduction of GG emissions

(Ton CO₂ eq.) |

2021 |

| Process redesign | 102.59 |

| Equipment conversion and adaptation | 14.16 |

| Fuel replacement | 0.00 |

| Change of employee conduct | 0.00 |

| Savings actions in process equipment | 5,692.25 |

| Total | 5,809.00 |

Note 1: The gases included in the calculation were CO₂.

In scope 1, we saw an increase of 1,544 T of CO2e (17%) with respect to 2020. The foregoing since greater production resulted in greater fuel consumption. In scope 2, we achieved a reduction of 5,809 T of CO2e (36%) with respect to 2020 due to the increase in consumption of clean energy.

305-4. Intensity of greenhouse gases

Considering the emissions from plants and distribution centers at the same time, including in these emissions those that are direct (mobile and fixed sources) and indirect (electricity from non-renewable sources), the intensity of GG emissions for 2021 was 0.106 Ton of CO2e/Ton produced, which represents an approximate reduction of 15.9% year over year. Unlike in 2020, for the year 2021, the consumption of electricity from the Cogeneration Plant in the Barilla and McCormick (Duque de Herdez) Plants, and the San Luis Potosí Distribution Center was declared with 0.00 emissions since, due to the SBTI analysis and to not duplicate accounting of Group level emissions, the emissions generated by this type of source were assigned directly to the Cogeneration Plant in scope 1 for its consumption of natural gas. The intensity of GG emissions is expressed in tons of CO2e per tons produced, and it is expressed based on the sum of direct and indirect emissions reported in the prior emission indicators, adding the emissions from fuel consumption and emissions due to consumption of electricity from the Federal Electricity Commission (CFE).

305-2. Indirect Greenhouse Gas Emissions (Scope 2)

Total indirect emissions

(Ton CO2 equivalent)

2021- 10,337

2020 – 16,146

2019 – 25,019

Notes:

We made an adjustment to the 2020 figures, eliminating the Avomex plant, which does not belong to the own operations of Grupo Herdez.

The gases included in the calculation were CO₂e.

In 2021, we had a slight increase in the amount of electricity from wind sources supplied to our plants.

The electricity generated by the Cogeneration Plant was sold to the facilities of Grupo Herdez (Barilla, McCormick (Duque de Herdez) plants, and San Luis Potosí Distribution Center), and the other part of the electricity generated was used by the Cogeneration Plant for self-consumption.

In the 2020 report for the Barilla, McCormick (Duque de Herdez) plants, and San Luis Potosí Distribution Center, we reported generation of emissions from electricity sold by the Cogeneration Plant. However, in 2021, this consumption of electricity was deemed ZERO emissions since, due to a recommendation of the SBTi methodology, emissions derived therefrom were fully counted for the Cogeneration Plant, since it is the one that uses the fuel for generation, sale, and self-consumption of electricity, and to prevent a double accounting of emissions.

305-1. Direct Greenhouse Gas Emissions (Scope 1)

| Direct emissions from fuel consumption in fixed sources | ||||

| Source | Fuel | 2021 | 2020 | 2019 |

| Ton CO2 equivalent | Ton CO2 equivalent |

Ton CO2 equivalent |

||

| Primary | Natural Gas | 26,494 | 22,433 | 12,330 |

| Secondary | Fuel Oil | 21,134 | 16,573 | 13,067 |

| Secondary | Waste fish oil | – | – | 277 |

| Secondary | Industrial Diesel | 133 | 1,116 | 1,084 |

| Secondary | LP Gas | 2,338 | 2,295 | 7,028 |

| Secondary | Gasoline | – | – | – |

| Subtotal | 49,999 | 42,418 | 33,786 | |

| Direct emissions from fuel consumption in mobile sources

|

||||

| Source | Fuel | 2021 | 2020 | 2019 |

| Ton CO2 equivalent |

Ton CO2 equivalent |

Ton CO2 equivalent |

||

| Secondary | LP Gas | 1,295 | 1,487 | 1,595 |

| Secondary | Marine Diesel | – | – | 30,649 |

| Secondary | Industrial Diesel | 4 | 17 | 16 |

| Secondary | Gasoline | 35 | 60 | 287 |

| Secondary | Jet Fuel | – | – | 609 |

| Subtotal | 1,334 | 1,563 | 33,156 | |

Note:

The totals are considering decimal differences.

We made an adjustment of the 2020 figures, eliminating the Avomex plant, which does not belong to the own operations of Grupo Herdez.

Total Direct Emissions

(Ton CO2 equivalent)

2021 – 51,334

2020 – 43,982

2019 – 66,942

Note: The gases included in the calculation were CO₂, CH₄, and N₂O.

Emissions of biogenic CO2 have not been determined at Grupo Herdez for any type of waste or biomass generated, since the volume of waste sent for processing, such as alternative fuels (waste biomass) is so small that it does not represent a significant impact in determining group-level emissions. More than 86% of waste generated is recycled, and the rest is sent to sanitary landfills and controlled confinement in the case of hazardous waste.

In the case of Greenhouse Gas (GG) emissions from direct sources (fixed and mobile -for use of fuel-), there is currently no single base year, we make an annual comparison of indicators taking the immediately previous year as the reference.

For direct and indirect sources, we used the direct estimate methodology, using emission factors established in internationally recognized sources, some of them adopted by the SEMARNAT, which, due to the units in which they are expressed, were directly applied to consumption of each of the fuels reported to estimate the tons of CO2e. For this determination, we worked under the assumption that Grupo Herdez does not have direct or accidental emissions or releases (whether leaks or spills) of HFC, PFC, SF6, and/or NF3 that may be deemed part of emissions to the atmosphere.

For direct (fixed and mobile) sources, the emission factors were taken from GHG-PI version 4.0 (fixed sources) and 2.3 (mobile sources).

302-4. Reduction in energy consumption

In 2021, we had a 6.0% increase in energy consumption due to a 6.6% increase in production, therefore, we consumed more fuel. At the Cogeneration Plant, we had an increase in production of electricity, which caused greater consumption of natural gas.

302-3. Energy Intensity

Regarding electricity consumption, energy intensity for 2021 was 136.71 Kwh/ton produced, i.e., a 5.4% increase from the previous year, where 129.65 KWh/ton produced was consumed. This, due to greater annual production in 2021.

Regarding fuel consumption, energy intensity for 2021 was 22.84 m3/ton produced, i.e., 18.9% more than the previous year, where the intensity was 19.21 m3/ton produced. This was due to greater production and also to greater consumption of fuel at the Cogeneration Plant.

The total energy intensity of the group in GJ/Ton produced was 2.05, i.e., 14.5% more than the previous year.

- 2021: 2.05 GJ/Ton produced

- 2020: 1.79 GJ/Ton produced

- 2019: 2.35 GJ/Ton produced

Note: We made an adjustment to the figures, eliminating the Avomex plant that does not belong to the own operations of Grupo Herdez.

302-1. Energy Consumption

Fuel Consumption

2021 – 902, 353 Gj

2020 – 802,955 Gj

2019 – 975,667 Gj

Type of Fuel

Natural gas: 546,661 GJ

Fuel Oil: 295,988 GJ

Industrial Diesel: 1,941 GJ

LP Gas: 57,238 GJ

Gasoline: 525 GJ

Electricity Consumption: 79, 274, 501 kw

| Electricity Consumption | GJ | KWh |

| 2021 | 285,388 | 79,274,501 |

| 2020 | 446,882 | 124,133,839 |

| 2019 | 285,855 | 79,404,224 |

Regarding the absolute total, in 2021, we consumed 1,187,741.15 GJ, a 6% increase with respect to 2020, where we consumed 1,122,684.94 GJ (figured adjusted for this report, since the one published in 2020 included Avomex, which plant does not belong to the own operations of the Group).

The increase is due to the fact that in 2021 we had 6.6% more production than in 202, which resulted in greater energy consumption, mainly fuel. Additionally, the Cogeneration Plant also had an increase in the production of electricity, which caused greater consumption of natural gas.

Our calculation methodology is based on converting consumption in m3 of fuel to caloric units (Gjoules and of the KWh of electricity consumed, to Gjoules through conversion factors applicable nationwide.

415-1. Political Contributions

In compliance with our Code of Ethics, which establishes the obligation to maintain a strictly neutral position on matters of politics and religion, at Grupo Herdez and its subsidiaries, we do not make financial and/or in kind contributions to political parties or related institutions: we also do not receive financial aid from the government.

We have an Ethics Committee composed of 6 members of different departments, which join their efforts with our directors to provide advice regarding ethical and legal conduct.

You can check our Code of Ethics at:

https://grupoherdez.com.mx/storage/2021/10/Codigo-de-Etica_18.5×13.5cm-2020_HQ.pdf

205-3. Confirmed cases of corruption and measures adopted

In 2021 we confirmed 7 cases of corruption, 3 more cases than last year. All of these cases resulted in the Company cutting ties with all people involved.

205-2. Communication and training on anticorruption policies and procedures

All of the 9 members of the Board of Directors (100%) receive and are aware of the Group’s anti-corruption policies:

- Code of Ethics

- Policy on Illegal Payments and No Bribery.

- Conflict of Interest Policy.

- Gifts Policy.

In 2021, we informed to:

- 7,095 collaborators (69% of total) on anti-corruption policies and procedures of the organization.

- 6,430 collaborators (62% of total) took classified courses on Ethics and Legality, with 9,225 hours invested.1,148 new business partners (100% of total) signed our Vendor Code of Conduct (this Code contemplates our policies), since it is an indispensable requirement to establish a business relationship.

From the training team, we conducted efforts aimed at informing and/or reinforcing knowledge of our policies and procedures, including those related to anti-corruption.

COMMUNICATION

Throughout the year, we implemented a communication campaign called “Non-Negotiables of the Code of Ethics” in which we included two anti-corruption related communications:

– Fraudulent Conducts: This communication was sent by email and placed in the bulletin boards of the plants.

– Illegal Payments: This communication was sent by email and placed in the bulletin boards of the plants.

TRAINING

– Training of the Code of Ethics: 5,078 collaborators(49% of total) received training on matters related to the Code of Ethics, whether in courses with this name or institutional induction courses.

– Annual Endorsement of the Code of Ethics of 1,632 trained collaborators (16% of total).

– Culture of Legality Course:

In this program, we trained 4,143 collaborators (40% of total) virtually, remotely, and in person.

– Legality Ambassadors: We trained 48 legality ambassadors (collaborators that held helped on this subject at our locations) in groups organized by Grupo Herdez. 8 additional ambassadors were trained in groups organized by Consejo Mexicano de Negocios and México Unido Contra la Delincuencia.

In total, we have 14,344 records of people that received communications and training.

Note: The members of the Board of Directors, collaborators and business partners trained in a culture of legality or who receive communication of the policies and procedures are from all regions where the Group has operations and from all labor categories for collaborators.

205-1. Operations assessed for corruption-related risks

At Grupo Herdez, the Human Resources Department, jointly with the Internal Audit are commissioned with monitoring all complaints for violations of the Code of Ethics, including complaints and reports regarding corruption and money laundering, in addition to human rights violations, workplace violence, and psychosocial risks. We do not make a formal analysis of the risks related to these issues, however, through this monitoring, it is possible to detect the subjects that arose with the greatest incidence: abuse of authority, abuse of trust, preferential treatment, theft of goods, conflicts of interest, and thus established the necessary measures to prevent actions of this kind.

We do not consider the number of operations but rather of cases, and we respond in indicator 205-3.

IP-3. Eating Healthy

Healthy Eating Program

The Healthy Eating Program provides food advice to our collaborators to modify their habits through balanced food plans and monthly consultations.

In 2021, we provided 1,286 remote nutritional consultations, 6% more than the prior year. A monthly average of 117 collaborators in Mexico City, State of Mexico, and Los Mochis. Between all participants, they were able to lose 466 kg, 60% more than in 2020.

A Summer with Grupo Herdez. With the goal of promoting a culture of healthy eating among the children, for 4 months, we published infographics related to eating healthy and capsules preparing fun dishes in the online platform Papalote en Casa. We were able to reach more than 347,000 people..

Navegantes en la Cocina

In November 2021, Saber Nutrir®, in collaboration with Fundación Herdez and Ediciones el Naranjo, published the book “Navegantes en la Cocina”, a story that seeks to approach children with the goal of contributing to their education regarding good eating habits.

We also had nutritional talks with the goal of discovering the riches and variety of the food that composes our diet, and promoting the bases for healthy eating. The total interactions of the digital activities reached 12,400 people.

IP-5. Type and rate of injuries, professional sickness, lost days, absenteeism, and work-related mortal victims

The Environmental, Health, and Safety (CASH) Control department maintains a culture of prevention, taking care of the integrity and continuity of the business, therefore, this year, we reduced the number of accidents by 44.3%, and regarding absenteeism, we had 71.2% less lost days, thanks to home office flexibility and timely follow-up of health protocols for all collaborators.

| Gender | Accidents | Accident rate* | Lost days due to accidents | Rate of lost days due to accidents** |

|---|---|---|---|---|

| Women | 36 | 0.66 | 609 | 11.2 |

| Men | 43 | 0.57 | 681 | 9.1 |

| Total | 79 | 1.24 | 1,290 | 20.3 |

| Man-Hours Worked | |

|---|---|

| Women | 10,827,648 |

| Men | 14,985,984 |

| Total | 25,813,632 |

(*) The rate of accidents expresses the number of accidents in the year in connection with the total man-hours worked, multiplied by the factor 200,000.

(**) The rate of days lost is expressed by comparing the total days lost in the year with the total man-hours worked, multiplied by the factor 200,000.

Note: The information presented herein covers all collaborators of the Group, since the Company does not have outsourced personnel.

Extraction of information from the absenteeism registry.

403-8. Health and safety management system

The Environmental, Health and Safety (CASH, for its acronym in Spanish) Control department monitors our health and safety management system. Such systems are applicable for all facilities of Grupo Herdez, including plants, distribution centers, stores, and corporate offices. Additionally, it covers all personnel that work inside our facilities. The occupational health and safety management systems implemented apply for all employees and for workers that are not employees of Grupo Herdez.

100% of workers are covered under this management system, and 94% of these are subject to an internal audit.

403-7. Impact prevention and mitigation

The company has an Industrial Safety Policy that applies to any person that works at the facilities of Grupo Herdez and applies to all hired or outsourced personnel. It focuses on minimizing unsafe conditions and acts, complying with the effective regulations applicable inside Grupo Herdez.

403-6. Employee Health Promotion

Grupo Herdez facilitates access for workers to medical and health services. We have the following mechanisms:

| Strategy | Scope | Evidence |

|---|---|---|

| File creation | Worker agreement evaluation | Medical test of personnel |

| Medical office in the case of plants | All workers | Medical consultations and recording thereof |

| Creation of internal health campaigns | Integrating workers where applicable | Assistance or evaluation lists |

| Work risk test | Where work considered risky is required | Medical evaluation and/or work permit |

| Private Institutions | All workers | Service agreement or purchase orders |

| Regulatory Health Studies | Audiometry Chest X-ray |

|

| Annual health campaigns | Prevention campaigns for personnel on health talks given by outside personnel | |

| Internal nutrition program for personnel in overweight and nutritional control situations | All workers |

Additionally, we offer non work-related voluntary health promotion services and programs:

| Service / Program | Description | Evidence |

|---|---|---|

| Medical guidance in case of disease | Workers must tell their immediate superior any anomaly or physical discomfort to be sent to and addressed in the plant medical service, where medical guidance is evaluated and given. | Medical pass, intentions log. |

| Prevenimss | Prevenimss campaigns with vaccine application, size, weight, pressure measurements, etc. | |

| Seasonal Diseases | Bulletins to prevent seasonal diseases in the summer, autumn, and winter. | |

| ISEMIM health campaigns | Deworming, breast cancer, prostate cancer campaigns, etc. | Photographs,records. |

| Government hospitals | Prevention campaigns, conferences. | Attendance lists, records. |

All medical information of collaborators is strictly confidential. To ensure the foregoing, we have our Code of Ethics.

- 01800 Line (01800 CONFIANZA – 01800 266342692).

- Trust Email (confianza@herdez.com).

- Suggestions Box.

These mechanisms are available 365 days a year, 24 hours a day.

403-5. Health and Safety Training

| Training | Description / Subjects |

|---|---|

| Safety Induction | Identification of unsafe acts and conditions, safety policies, regulations, and management systems |

| Standards of the Ministry of Labor and Social Welfare (STPS) | Annual training on the applicable standards of the STPS for knowledge levels of all operating personnel and domain levels for specialized personnel, according to the worksite, including risk analysis and job security analysis. |

| SafeStart | Safety philosophy promoting a culture of safety through personnel awareness generating safety habits that reduce the occurrence of injuries caused by states of human behavior, critical errors, and the practice of error reduction techniques (5 modules). |

| Lockout-Tagout (LOTO) | Technical training in application of lockout systems for crucial operation, maintenance, and cleaning works where it is necessary for the personnel to intervene in moving equipment and/or use energy for the purpose of eliminating hazardous energy that puts collaborators in danger. |

| Emergency response | Personnel training in applicable emergency response activities in operations such as: natural disasters, firefighting, first aid, evacuations, search, rescue, spill, sabotage response, etc. |

| Property Security System | Property safety (facilities, personnel safety, training, transportation, reporting culture, computer systems, internal processes) |

| Direct Observation Work System | Safety for identification and correction of unsafe workplace acts. |

403-4. Employee participation and consultation

Grupo Herdez has different processes to promote participation of and consultation with workers in developing, implementing, and evaluating the management system. Additionally, to provide access and communicate relevant information on occupational health and safety to workers, such as:

| Industrial Safety Policy | Grounded on the commitment of the Chief Executive Officer. It considers issues such as health, safety, and the environment. |

|---|---|

| 5 S´s System

|

We comply with the 5S’s program through visible standards by departments and regulations for easy comprehension and identification of the entire personnel. |

| Bulleting boards, CASH, and factory

|

We develop the deployment of information on campaigns, calls for participation in activities on matters of workplace health and safety, and accident probability indicators. |

| Comprehensive Management System | We make carry out scheduled tours and/or audits to assess compliance, and otherwise establishing action plans corresponding to the findings thereof, and we provide feedback for continuous improvement. |

| Communications, bulletins, brochures, and visual aids | We generate information brochures with relevant information with scheduled events regarding health, safety, and/or environmental matters. |

| Health programs | Based on the provisions of the annual health programs, we carry out different occupational health campaigns, such as: vaccination, early detection of chronic degenerative diseases, among others, and follow-up on these. |

We have health and safety management committees to timely follow-up on each relevant matter described as follows:

| Committee | Duties | Meeting Frequency | Level of Authority |

|---|---|---|---|

| Health and Safety Commission

|

Strategic tours to recognize unsafe acts and/or conditions | Monthly | Medium |

| CASH Pillar | Execute and implement the safety methodology, participating in the analysis of accidents, actions, and early response to unsafe conditions. | Weekly | High |

| Strategic plant committee | Decision-making for important strategic points | Monthly | High |

| CASH (Environmental, Heath, and Safety) | Duties of the occupational health and safety management | Weekly | High |

| Crisis Committee | It establishes actions to give continuity to the operations during covid-19 | Daily | High |

Additionally, we have formal local agreements with unions, for the benefit of workers on occupational health and safety matters, such as: emergency brigades, evacuation, firefighting, fighting diseases and work accidents; health and safety campaigns; workplace risk prevention system, and all provisions of laws, regulations, and Mexican Official Standards.

403-3. Occupational health services

The participation of the Occupational Health service (Medical Service) starts with a safety tour program, highlighting unsafe conditions. Based on the obtained risk mapping, an annual program of general and special tests is established, with spirometry, audiometry, vibrations, depressed and/or elevated temperature conditions, etc.

Medical files are strictly confidential, solely for doctor-patient knowledge.

403-2. Hazard and Risk Identification

The processes used to identify work risks and assess risks periodically or sporadically are performed from the Environmental, Health, and Safety (CASH) department.

In the STOP system, we analyze the number of unsafe acts and conditions. The accident ratio and safety pulse has the goal of being above 94%.

The indicators are reviewed and analyzed on a weekly basis with the safety leaders, together with the progress that they had in their regulatory folders.

The monthly and annual results are sent to local management departments (plants, for example), CASH department and supply chain department, and work plans and the “logic tree” related to the CASH department are created based on results.