Our environmental commitment has a preventive focus that favors sustainable development, promotes initiatives, and disseminates new technologies to reduce environmental impacts on our operations, within the directives and scopes in the environmental management system.

Recognitions for our environmental management

ISO 50001 Certification (energy management)

Our Ice Cream plant, located in Lagos de Moreno, Jalisco, obtained the ISO 50001 certification. This certification certifies that our energy management system has the highest standards of efficiency and safety on the subject matter, through a continuous and systematic improvement for energy use, consumption, and efficiency.

ISO 14001 Certification (environmental management)

Our Ice Cream plant, located in Lagos de Moreno, Jalisco, obtained the ISO 14001 certification. This certification certifies that we have a management system to control and mitigate the environmental impacts of our operations according to the line of business and scope of the plant.

FSC LEADERSHIP AWARDS for Del Fuerte®

Our Del Fuerte® Brand was recognized by the Forest Stewardship Council by the “A Stronger Legacy” (Un Legado Más Fuerte) program. This environmental and social impact was recognized for the conservation efforts of the bodies of water that supply the tomato fields in Sinaloa, where we obtain most of the raw materials for the Del Fuerte® products. Additionally, this initiative obtained 1st place in the Forest Conservation category in the Bóscares Awards of Reforestemos México.

MERCO ESG environmental responsibility

The Merco ESG Reponsibility ranking is one of the most important corporate reputation monitors in Mexico, Latin America, and Spain where we were ranked fourth in the list of “The 100 most environmentally responsible companies”.

We received the CHEP sustainability certificate as a result of maintaining use of sustainable pallets in our supply chain. For both companies we were able to reduce, only with the use of pooling, more than 3.1 million emissions of CO2, and prevented the use of wood for construction of new pallets, equivalent to cutting 23,171 trees.

Water

In 2021 we had a decrease in water consumption of 4.4% referring to absolute m3, due to the improvement initiatives for resource savings implemented in our different locations.

The total volume of water discharges increased 6.4% in absolute m3, due to the increase in the number of equipment and facilities washing, which were implemented for health and safety reasons motivated by the pandemic.

Compared with discharges per ton produced, there is no increase, since for both years there is an indicator of .75 m3 per ton produced.

Energy

In 2021 we had a 6.0% increase in energy consumption, due to a 6.6% increase in our production, therefore, we consumed more fuel. In our Cogeneration plant, there was an increase in energy production, which caused greater consumption of natural gas.

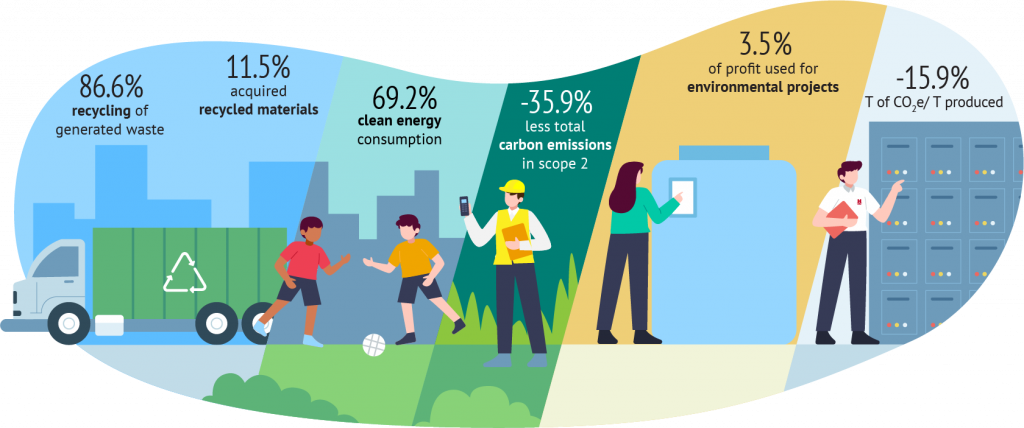

Consumption of energy from clean sources during 2021 was 69.2%

- Renewable energy (wind): 41.5 %

- Clean energy (cogeneration): 27.7%

Emmisions

In 2021, the intensity of Greenhouse Gas Emissions (GGE) was 0.106 tons of CO2e per ton produced (T de CO2e/ T produced), which represents a 15.9% reduction with respect to the preceding year.

In scope 1, we had an increase of 1,544 T of CO2e (17.0%) with respect to 2020, due to greater production derived from greater consumption of fuel. In scope 2, we obtained a reduction of 5,809 T de CO2e (35.9%) with respect to the prior year, due to the increase in consumption of clean energy.

Materials and waste

We consume 3 categories of materials: agricultural raw materials, non-perishable raw materials, and packaging materials (non-renewable and renewable).

87.7% of raw material suppliers are domestic.

13.7% of the total acquired material was recycled, which included corrugated carboard in small boxes, boxes, and trays.

This year we generated 31.6% more hazardous and non-hazardous waste with respect to last year, due to an increase in production and greater control of health and safety conditions as a result of the pandemic, in addition to generation and handling of greater volumes of obsolete equipment. To compensate this increase, we were able to increase recycling of the waste generated in the operation by 86.6%.

Circularity

We seek to use natural resources efficiently in our production processes, and integrate our consumers in initiatives that add to reduce environmental impact on our packages. This way, we take advantage of waste, we reintegrate it to the production cycle and satisfy our current needs without jeopardizing the availability of resources for the future.

Circularity initiatives

This year, we prepared the Circularity Graphic Guide for the purpose of aligning communication on the optimal disposition of the packaging and containers of the products we prepare. By applying the guide to our labels, our consumers will know the material, recyclability, and reuse of materials, and add to taking care of the planet.

As of this year, paper labels are printed in vegetable ink for Herdez®, Doña María®, McCormick® jellies, and Búfalo® (conventional) products.

The packets of our McCormick® teas are now printed in SAPPI Seal Silk sustainable material, replacing more than 750 tons of BOPP film per year. Additionally, continuous labels are printed in water-based ink.

In 2021, we recovered and recycled 4.5 tons of tin, with the “Recicla la lata“ initiative. The material collected will be used to build 5 clean energy systems that will be donated to communities that do not have access to other electricity services.

Aires de Campo® in alliance with Ecolana launched the first glass recycling campaign in Mexico City and Querétaro. The locations of Cerrando el Ciclo and Ectágono were the collection points, where we were able to recover 6.5 tons of glass from consumers.

Supply Chain

Collaboration with our suppliers throughout the value chain is key to guaranteeing the quality and safety of all products that we market. Their experience, combined with our best practices, guarantee for our consumers unique products in the market, with the highest quality.

- The Sustainable Agricultural Program evaluates suppliers every 6 months, complying with the rules checklist. In the first semester of 2021, we had 32 evaluated suppliers, at the end of the year, we completed the evaluation with 30 suppliers. 29 of the 30 suppliers complied with the program.

- We started the sustainability progress level evaluation program for 100 of our main suppliers, in alliance with IKUS. The 2025 objective of this evaluation is to guarantee a supply chain with sustainable criteria in at least 70% of our purchases.

- Aires de Campo®, in alliance with other producers, planted 800 hectares of organic crops, favoring soil restoration and no contamination with agrochemicals.